How do composting toilets work?

Composting toilets provide a hygienic method of recycling human waste. They avoid the need to waste and pollute precious water.

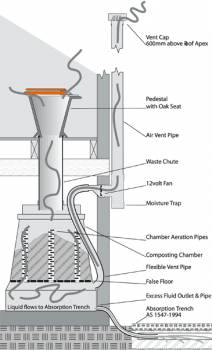

The waste is collected in a small chamber directly beneath the toilet pedestal. A low-powered 12-volt fan continually circulates air through the composting chamber, evaporating liquids, speeding the composting process and eliminating odours.

The working principle of batch-type composting toilets

The batch-process compost toilet models come with at least two composting chambers. Use and fill one, put it aside to continue composting, and put the second chamber into use. By the time you need to change chambers again, the contents of the first chamber should be well and truly composted. Just remove the digested compost, put it in your garden or bury it, and re-use the cleaned chamber.

The modular batch system means that capacity is virtually unlimited. If usage increases, buy an additional chamber and rotate the chambers more often.

Good composting is achieved by ensuring correct levels of moisture, oxygen, temperature and carbon/nitrogen ratio. All compost toilet systems require ventilation, and drainage to take away excess liquids from the solids, and to provide adequate oxygen. Warmth is developed inside the pile itself and by exposure of the chamber to direct sunlight. Carbon-rich mulch is added when in use to maintain the correct carbon to nitrogen balance, and to provide better ventilation of the pile.

Keeping your compost toilet clean and fresh is incredibly simple. Just as with a conventional flush toilet, you may need to give it an occasional scrub with a toilet brush. When you do, use biodegradable detergent, vinegar solution, or Nature-Flush enzymes. Never use disinfectant chemicals or chlorine bleach.

A properly working compost toilet system is completely free of chemicals and odours.

Installation

Even a complete novice can install a compost toilet in about half a day.

All you need is a clearance of height 850mm or less, and around one-metre space beneath your toilet room. In the cases of using the self-contained single units, the entire unit sits directly on the floor.

The compost toilet does not need to be installed on the north side of a house because all chambers eventually get exposed to direct sunlight, once full and out-of-service.

Moisture

The moisture content of a compost pile is very important. Below 40%, the organic matter will tend to dry out and not decompose rapidly. Over about 60%, not enough air can get into the pile, and the process can become anaerobic (no oxygen) and may start to smell.

Moisture content of approximately 50% is ideal for composting. The naturally high moisture content of fresh human waste is reduced by draining excess liquid through the perforated floor into the liquid chamber. This prevents the process from becoming anaerobic.

When the chamber is full and left to stand in the sun, no additional liquid is being added and the moisture content falls rapidly. Direct exposure to sunlight further reduces the moisture level. Unlike other types of composting toilets, there is no requirement to only position the toilet on the sunny side of the building.

Oxygen

Micro-organisms that require oxygen to survive are called aerobes. Organic materials are decomposed most rapidly by aerobes ~ much more rapidly than the anaerobes used in septic systems.

Aerobes need many cubic metres of oxygen per day for rapid breakdown. A small ventilation fan provides up to 420 litres of air per minute, more than enough to keep the process going at optimum levels. This has the added advantage of acting as a highly efficient extractor fan to remove any rising odours from the toilet room.

Temperature

The heat coming from piles of organic material is generated by the feeding and multiplication of millions of microorganisms. Technically, the stage of the temperature cycle below 40 °C is termed mesophilic, above 40 °C is thermophilic.

Composting is most rapid in the thermophilic stage. As the temperature rises over 40 °C, mesophilic organisms die out and are replaced by an upsurge in the population of thermophilic organisms; the agents of fastest decomposition.

Compost toilets function well in both thermophilic and mesophilic stages, but in most cases, they operate faster in the thermophilic stage. This happens for a couple of reasons:

Air is drawn into the compost toilet chamber through the toilet pedestal. As the air inside a house is usually warmer than the air outside, the chamber is also kept warmer. In colder climates, the chamber may be insulated with thermal insulation material, to maintain the composting rate.

The containers are black. This means they are an excellent absorber of heat, especially if located in natural sunlight as is recommended once they are full. Unlike most other composting toilets where the chambers are located under a house, the full chambers are exposed to natural sunlight for at least 50% of the composting cycle.

Pathogens

An important function of the composting process is the destruction of pathogens. Most are killed in the thermophilic stage. Composting at temperatures above 55 °C for one day kills almost all pathogens.

As the compost chamber is in use for around 6 months and is composting by itself for another 6 months, there is little chance of any pathogens surviving, even if the composting process does not reach the thermophilic stage. In addition, the unique use of isolated chambers ensures no recontamination from fresh waste.

Since a chamber’s internal temperature can reach 45 degrees centigrade in winter in Northern NSW, there is little chance of any pathogen surviving a number of months under such conditions, even in cooler climates. A typical analysis of the humus from a fully digested compost toilet shows no traces of Faecal Streptococci, Faecal Coliforms or Salmonella sp.

The working principle of Sun-mar continuous-type composting toilets

Composting is Nature’s Way. Every living organism consumes nutrients and creates waste. To transform waste back to nutrients and complete this cycle, nature uses the processes of decomposition and evaporation. As is often the case, nature seems to be doing business in the best way possible.

That’s why Sun-Mar toilets are designed not only to harness these natural processes, but to optimize and accelerate them.

Toilet waste is over 90% water content. This can be evaporated and carried back to the atmosphere through the vent system. The small amount of remaining material is recycled into a useful fertilizing soil.

Wherever there is a poorly working septic system, a Sun-Mar can take care of the toilet waste; where there is an outhouse we offer the luxury of an indoor facility; and where there is no toilet at all, a Sun-Mar provides the right environmental choice. Sun-Mar units are economical, quick to install and easy to use.

Because no chemicals and no septic systems are used, fragile environments can be protected. A Sun-Mar composting unit is an environmentally healthy choice for recycling human waste. The Sun-Mar system produces no pollutants, while collecting nutrients. With a Sun-Mar, recycling is made easy!

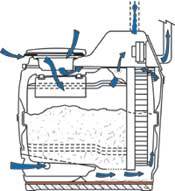

Odour Free

As well as ensuring an aerobic breakdown in the Bio-drum, Sun-Mar ensures an odour free environment by engineering the air flow within the unit to maintain a partial vacuum at all times. Air is being drawn in either by a fan (or on non-electric units by the vent chimney) over the evaporating chamber and up the vent stack. Not only does this evaporate excess liquid, but by continuously pulling air in we ensure no smell escapes from the unit.

Evaporation is assisted on electric units by a thermostatically controlled heater in a sealed compartment underneath the evaporating chamber.

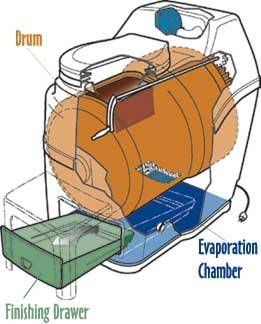

Sun-Mar’s Unique Bio-Drum

The ideal way to compost waste would offer operational simplicity and an environment where there is warmth, moisture, organic material, and oxygen. Sun-Mar creates this ideal environment in the patented Bio-drum.

The unique Sun-Mar Bio-drum ensures aerobic microbes flourish and work much more quickly to break down waste and convert it back to earth.

Operational Simplicity

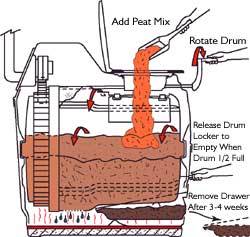

Waste and peat mix bulking material enter through the waste inlet port at the top of the drum. To mix and aerate, rotate the drum periodically, simply by turning the handle on the front of self-contained units or on the side of central units. During rotation the inlet door closes automatically keeping the compost in the drum.

To empty compost from the Bio-drum simply release the drum locker and rotate the drum backwards. Now, the inlet port in the Bio-Drum opens automatically and compost drops directly into the compost finishing drawer.

After rotating, the Bio-drum locks itself in a top dead centre position ready to receive new material.

Supplying Oxygen

Sun-Mar’s unique Bio-Drum design is the easiest and best possible way to thoroughly and completely mix and oxygenate the whole compost. Rotate the drum, and the entire compost pile is tumbled and infused with oxygen. Oxygen is one key ingredient which allows aerobic bacteria to break down waste quickly and without odor.

Controlling Moisture

Moisture control, the other basic requirement for good composting, is one of the outstanding benefits offered only by Sun-Mar’s Bio-drum.

Below 40% moisture content, composting slows and eventually stops completely. By not applying direct heat to the compost, Sun-Mar ensures that it does not dry out. In addition, the tumbling action during periodic mixing distributes moisture evenly throughout the compost.

At above 60% moisture content, liquid starts to drive out the oxygen in the compost, and the compost becomes increasingly anaerobic,- like a septic system. Sun-Mar’s unique Bio-drum optimizes composting speeds by automatically draining any excess liquid through a screen at the bottom of the drum directly into the evaporation chamber.

Maintaining Warmth

The microbes generate their own heat as they work. This warmth is held in the compost by the mass of material inside the drum, supported by indirect heat from the base heater (in electric units). By avoiding direct heat, Sun-Mar ensures that composting will not slow down as the material gets dried out.

The Ideal Environment For Aerobic Bacteria

Uneven distribution of oxygen and moisture allows anaerobic bacteria to take over. These microbes produce bad odors and do not allow the waste to break down quickly.

The superior oxygenation and moisture control provided by the Bio-drum provides the ideal environment for aerobic bacteria to odorlessly break down organic material. They quickly convert organic material into water and carbon dioxide, and leave behind simple salts which are ideal for uptake by plants.

Use and ongoing maintenance

Operating a Sun-Mar is easy. There are two things that you have to do on a routine basis – rotate the drum and add bulking material, at the rate of a cupful per person per day.

Add 1 cupful (or 2 handfuls) of Sun-Mar Compost Sure (or 50/50 mixture of peat moss and non-cedar wood shavings) to the Bio-Drum after every bowel movement. This usually represents one cupful per person per day of use.

If you have a central unit, peat mix only needs to be added when you do your rotations at the end of the weekend (cottage use) or once every 2nd day (residential/weekly use).

Why? Maintains the carbon/nitrogen balance, Absorbs Liquid, Helps oxygen penetrate for aerobic composting

Turn Handle to rotate the drum 4-6 complete revolutions, three times a week when in use, or, if used only at weekends, only on departure.

Why? Mixes and oxygenates the compost

Unplug the unit if you are leaving for a period of more than a few days. If you are leaving one weekend and coming back the next, you may unplug the unit.

Consider installing a timer to shut the unit off after 48 hours to evaporate excess liquid. If you are leaving for a period of more than few days, or the compost appears dry, add approximately 1/2 gallon of warm water before leaving to keep the compost moist.

Why? unplugging unit will conserve power and keep compost from drying. Addition of water helps keep the compost moist

Empty some compost into the finishing drawer when the drum is 1/2 to 2/3 full. It is 2/3 full when the compost reaches a level about 2-3 inches below the drum door when the door is open.

To empty some compost into the drawer, pull the drum locker button and rotate the handle counter-clockwise (to turn the drum clockwise). Turn at the same speed you would normally do for mixing.

If necessary, use the rake to level the compost in the drawer. If there is not enough compost in the drawer, turn the drum backwards (clockwise) again 1 rotation.

Leave the compost in the finishing drawer to finish for 3-4 weeks or until you next need to remove compost from the drum.

If your unit is used seasonally and is not used heavily, you may not have to remove any compost at all during the season. If so, follow “Annual Startup”.

Why? Moves some compost to the next stage for finishing, ensures that the drum does not get too full, provides Extra Time for composting to be completed.

Annual system start-up – What to do at the beginning of the holiday season

Empty any compost that had been left in the finishing drawer, and use the rake to clean out the evaporation chamber, paying special attention to the back two corners of the unit (or left hand side if it is a Centrex family unit).

Why? Your fertilizer is ready. This is a good time to remove peat debris from the evaporation chamber.

Remove additional drawers of compost (if there is more than 6 to 8 inches of compost in the drum). This is done by releasing the drum lock, and rotating the drum opposite from the usual direction (turn handle counter-clockwise) to extract compost into the drawer.

Since it will have been sitting over the winter and decomposing in the fall and spring, it will be finished and may be removed immediately, without any extra time needed to finish the compost in the drawer. Several drawers may be removed in this fashion if necessary.

Be sure to leave 6-8 inches of compost in the bottom of the drum to start off the season with a “starter batch” of compost.

Why? Frees space in the drum for the new season’s composting

Add 1/2 gallon of warm water. Why? Raises moisture level as an option for optimal composting:

Add SUN-MAR “Microbe Mix” or unsterilized black earth from a garden center. We do not recommend using topsoil as it may contain fly larvae, and may not contain all of the bacterium required.

SUN-MAR “Compost Quick” enzyme can also be used as a compost accelerant. Even though the compost still has microbes in it, you may want to start the year by replenishing microbes.

Compost Quick helps to accelerate the action of the microbes

Evaporation chamber

Compost must be kept moist but not saturated. Excess liquid from the drum strains through a stainless mesh screen into the evaporation chamber. The ideal environment for evaporating any excess liquid is a large surface area combined with heat and moving air. Sun-Mar meets these criteria in the evaporating chamber.

Any liquid not absorbed by the compost in the drum drains through the screen directly into the evaporating chamber.

On all central units the liquid falls first onto an evaporating tray and then to the main evaporating surface. The tray not only helps oxygenate this liquid, it also traps any peat mix debris, and almost doubles the evaporating surface. Evaporating trays can be removed and cleaned if necessary, through the door opening on Centrex 1000 and 2000 units, and through the drawer access port on Centrex 3000 units.

For optimum results evaporation is assisted on 110 Volt electric models by a thermostatically controlled heating element. Sealed in a compartment underneath the evaporating chamber, the heater warms the floor of the evaporating chamber without drying out the compost.

In non-electric units, although some liquid is evaporated by passive venting, the overflow drains must always be connected.

Finishing drawer – Advantages of a separate compost finishing drawer

Composting can be completed in the drawer without contamination by fresh waste. Compost in the drawer is gradually dried until ready for removal. Finished compost can be simply and safely removed

The finishing drawer serves two functions: to receive the compost in an easily accessible isolated container, and complete the composting and sanitation processes.

All Units Except CENTREX 3000 Series

Compost drops directly into the finishing drawer when the drum is rotated backwards. Composting is completed in the drawer, where it is isolated from fresh waste and possible contamination. While in the drawer, the compost is surrounded by a stream of drying air, and gradually dries prior to removal.

The pull out finishing drawer is removed by hand (no tools or screws are needed), and the sanitized compost may be emptied whenever more compost is to be extracted from the drum.

For seasonal units, several drawers may be removed in the Spring, reducing the compost level in the drum to 6-8″ to make room for next year’s operation.

CENTREX 3000 Series Units Only

There are two compost finishing drawers in the CENTREX 3000 series units. Both are easily removed by hand and are interchangeable.

The first drawer is inside the collection housing at the side of the unit. This is where the finished compost automatically falls after leaving the second section of the Bio-drum.

The second drawer is located inside the unit. Moving compost from the first drawer to this second station allows the composting cycle to be extended if necessary. This can help ensure the compost is safe to handle.

For seasonal units, the second section of the drum can be emptied in the Spring by rotating the drum backwards and dropping compost into the second drawer.

If you have a question state it here and we will answer it for you.